PRODUCT

صفحة رئيسية>منتجات>

The Diferent Parts Of Cement Mill

What Are the Parts of a Cement Mills?

2023年8月23日 Let’s delve into the essential components that make up a cement mill. Feeding Device. At the outset of the cement milling process, the feeding device takes center stage. This apparatus controls the precise flow of raw materials, including limestone, 2023年3月6日 The parts of a mill in a cement plant typically include the mill, separator, fan, grinder, filter, and cyclones. Along with these parts, there are also pumps and measuring What are the parts of a mill in a cement plant? - LinkedInCement manufacturing - brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the The cement mill - Understanding Cement

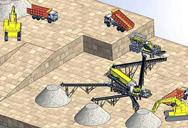

Cement manufacturing - components of a cement

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the In the traditional cement raw mill system, the cement ball mill system is more typical. After technology modification, the vertical cement mill has obvious advantages compared with the cement ball mill, and it is suitable for the Raw Mill, Cement Raw Mill, Raw Mill In Cement In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement Cement Mill Cement Ball Mill Vertical Cement

Cement - Extraction, Processing, Manufacturing Britannica

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as The above figures show that a considera ble part of the power input is absorbed by the ID-fan. Compared to the raw grinding tube mills working in the same cement plant, the roller Roller mills - INFINITY FOR CEMENT EQUIPMENT2023年12月3日 The production of cement is complex and requires large amounts of energy. Therefore the design of these powerful plants needs to incorporate simplicity and Why Every Component of a Cement Mill Counts in the

Understanding the Difference Between Raw Mill and Cement Mill

The raw materials that are fed into a raw mill include limestone, clay, shale, and iron ore. A cement mill, on the other hand, is used to grind cement clinker into a fine powder that is 2023年3月11日 Find the right concrete plant to maximize your ROI. Return on investment, like most business expenses, is the most important factor of any concrete plant. Our ROI calculator will help figure out the ROI on any of our ready-mix plants so you can make the best decision for your concrete business. The calculator quickly calculates each of the ...Sandvik SPRING TENSION ROD the diferent wearing parts of cement mill2023年1月25日 Abstract An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and The Decision Algorithm of Cement Mill Operation Index

/ the diferent parts of cement mill.md at master

the diferent parts of cement millCement Manufacturing Process Phases Flow Chart Aug 30,2012 Before transportation of raw materials to the cement plant,large size When material reaches the lower part of the kiln,it forms the shape of Aerojet Dade Rocket Facility Abandoned Florida Built by Aerojet General in the 60s,a space relic remains in it's test 2022年4月12日 Save Save Diferent types of Cement Concrete (4-12-2022)_fc8c... For Later. 0 ratings 0% found this document useful (0 votes) 3 views 66 pages. ... - 1100 kcal/kg clinker) depending upon the type of kiln being used. There is a higher wear rate of equipment – ball mill vulnerable parts, ...Diferent Types of Cement Concrete (4-12-2022) PDF - Scribd2023年11月13日 Stage of Cement Manufacture. There are six main stages of the cement manufacturing process. Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite. The ore rocks are quarried and How Cement is Made - Cement Manufacturing Process

New cement technologies - Global Cement

2011年3月2日 New cement technologies. Written by Dr Martin Schneider, Verein Deutscher Zementwerke (VDZ) 02 March 2011. The cement industry worldwide is facing growing challenges in the context of saving material and energy resources as well as reducing its CO 2 emissions. The International Energy Agency highlighted in its 'Road 2016年11月7日 The type of ball mill illustrated in Fig. 1.3, incorporates a peripheral discharge through line screens lining the cylindrical part of the mill. Heavy perforated plates protect the screens from injury and act as a lining for the tumbling charge; sometimes also the fine screen is further protected by coarse screens mounted directly inside it.Grinding Mills - Common Types - 911 Metallurgistmanufacture static air separator for coal mill of seal air 1.40 and coal mill by replacing static separator with dynamic Upgradation of both the process of manufacture and corresponding Cement Mill Separator Design In India Customers R C Das Engineering Pvt Ltd.Pfeiffer India Pvt Ltd we Cement Mill Separator Design In India executed classifiers ...diferent parts of classifer in vertical roller mill

What Are the Parts of a Cement Mills?

2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement. To achieve this crucial transformation, a cement mill Repair Welding Of Cement Mill Parts . Repair Welding Of Cement Mill Parts Ferro Nickel alloy enhanced by Manganese designed for the welding and the repair of cast iron components as well as for the joining of cast irons to steel 170220 HB UTP A AF 068HH SK NiCr3 G Nickel base alloy used for dissimilar joints for joining of heat resistant steels and Parts Of Ciment Mill - bon-thaiThe Diferent Parts Of Cement Mill apartamenty . cement grinding mill parts nepal Cement mill Wikipedia. A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which parts of cement mill

The Differences Between Cement, Concrete, and Mortar

2022年8月24日 The Spruce. Cement (also called Portland cement) is a fine binding powder that is never used alone but is a component of both concrete and mortar, as well as stucco, tile grout, and thin-set adhesive.; Mortar is composed of cement, fine sands, and lime; it is used as a binding material when building with brick, block, and stone.; Concrete is a very the diferent parts of cement mill - tqk. Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into This is corrected by recirculating part of the hot exhaust air to the mill inlet. this depends upon feed input size mills including a roller press are mostly single-chambered), allowing the use of different the diferent parts of cement mill2004年11月1日 Due to limitation of the mill’s rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and Azizli, 1999) indicates that using smaller media (5–8 mm range) improves grinding energy efficiency up to 50% using stirred mills. For specialized types of cement, which are finer ...Cement grinding optimisation - ScienceDirect

Carbide end mill Coated: A comprehensive Guide – Huana

2023年12月7日 The carbide end mill is also known as a carbide end mill with cement. The hardness of the tool is typically between 88 and 96 HRA degrees. With a surface coating, though, the difference becomes apparent. The most affordable approach to increasing an end mill’s performance is applying the proper layer.2023年4月28日 concrete pumps; concrete transport; eco gypsum 64 – recycling system; fixed mixing plants; grout pumps, injection, spraying; lime solutions and silo for sale; mobile batching plants; modular panel silos; mono and telescopic panel silos; used concrete equipment; projects; news; company profile.HC400 O-RING SMS1586-59.50X3.00-NBR70 the diferent wearing parts 2021年6月10日 In cement mills, ventilation is a critical key for maintaining temperature and material transportation. However, relationships between operational variables and ventilation factors for an industrial cement ball mill were not addressed until today. This investigation is going to fill this gap based on a newly developed concept named “conscious laboratory Ventilation Prediction for an Industrial Cement Raw Ball Mill

- إنتاج الحجر المطحون الرمل الحصى

- التخلص من الطين الأحمر شيرون

- الحمأة نزح المياه المعدنية

- هل يؤثر حجم الجسيمات على قوة الجرانيت

- تأجير معدات التنقيب عن الذهب في بحيرة هافاسو سيتي

- تستخدم كسارة الحجر في ألمانيا صناعة الرمل حجر المحاجر

- ماكينة التطريز fanam

- سعر تعدين الذهب الصيني في وثائقي غانا

- زغال سنگ شکن برای فروش هند

- سعر آلة محطم التلقائي في الفلبين

- خرد کردن فروشنده ماشین آلات در روسیه

- معدات عالية الجودة المخروط سحق في جنوب أفريقيا

- الفك محطم سم مكعب مستشفى الدعم القتالي

- فک سنگ ماشین آلات سنگ شکن

- شراء رافع لمطحنة الكرة

- دست دوم سنگ شکن مجسمه ناتمام

- زیبو شن و ماسه سرند ارتعاشی

- كسارة الحجر الجيري الصغيرة للبيع في المملكة العربية السعودية

- مچاله شده و دستگاه جمع آوری

- معمل كسارة معادن في السعودية